The waterborne technology is projected to grow at the highest CAGR during the forecast period. This technology is widely used in architectural, automotive, and industrial applications due to its low VOC content and environmental friendliness.

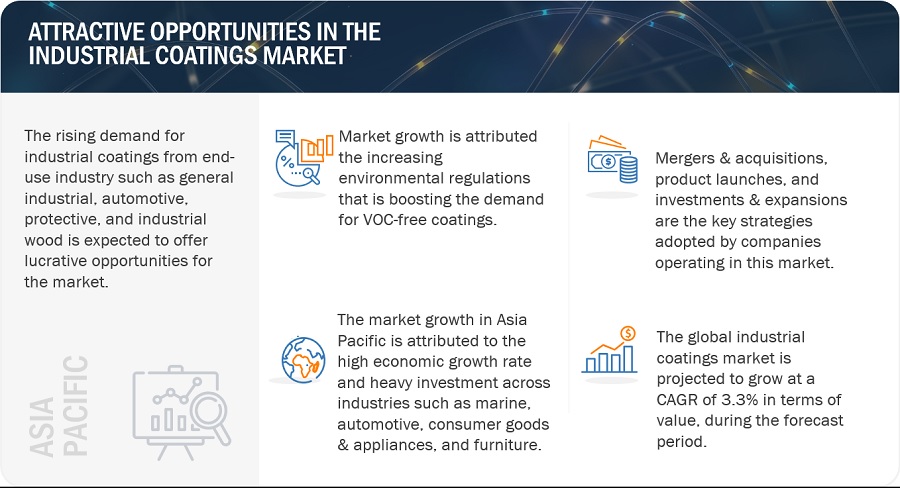

The Industrial coatings market size is projected to grow from USD 102.0 Billion in 2021 to USD 116.0 Billion in 2026, at a CAGR of 2.5%., according to a new report by MarketsandMarkets.

Waterborne technology is expected to account for the second-largest share of the industrial coatings market during the forecast period. The segment is projected to grow at the highest CAGR from 2021 to 2026. Waterborne coatings are eco-friendly and have low VOCs (volatile organic compounds). They offer better performance in terms of abrasion resistance and corrosion resistance and are easier to apply than solvent-based coatings.

The epoxy resin segment is expected to be the largest segment of the industrial coatings market during the forecast period. The high growth of this segment can be attributed to the superior properties of epoxy resins, such as chemical resistance, durability, and adhesion. Epoxy resins are widely used in automotive, aerospace, and construction applications.

The Asia-Pacific region is expected to be the largest market for industrial coatings during the forecast period. The region's large population and rapidly growing economy are driving the demand for industrial coatings in the region.

Download PDF Brochure https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=746

What is waterborne technology?

Waterborne technology is a type of coating that is applied using water rather than solvent-based chemicals. This type of coating is typically more environmentally friendly, as it produces fewer harmful emissions. Waterborne technology can be used for a variety of applications, including automotive coatings, architectural coatings, and industrial coatings.

What are the benefits of waterborne technology?

Waterborne technology is quickly becoming the preferred method for industrial coating applications. Waterborne coatings offer a number of advantages over traditional solvent-based coatings, including improved safety, lower environmental impact, and better performance.

Waterborne coatings are typically made from acrylics, polyurethanes, or epoxies. These materials are suspended in water and applied to surfaces using conventional spray guns or rollers. The water evaporates as the coating dries, leaving behind a thin film of protective material.

Waterborne coatings offer a number of advantages over solvent-based alternatives. They are safer to use and have a lower environmental impact. Waterborne coatings also tend to be more durable and perform better in extreme conditions.

How is waterborne technology used in industrial coatings?

Waterborne technology is used in industrial coatings to create a variety of finishes, including high-gloss, semi-gloss, and matte. This type of technology can be used on a variety of substrates, including metal, plastic, and glass. Waterborne industrial coatings are typically applied using a spray gun.

What are the global market trends for waterborne technology?

This growth can be attributed to the increase in demand for environment-friendly and energy-efficient products. Moreover, the rising awareness about the health hazards posed by volatile organic compounds (VOCs) is also expected to fuel the growth of the waterborne technology market.

Conclusion

In conclusion, the global industrial coatings market is expected to grow 2021 to USD 116.0 Billion in 2026, at a CAGR of 2.5%. The market will be driven by the rising demand for durable and corrosion-resistant coatings from end-use industries such as construction, automotive, and packaging. Moreover, the growing preference for waterborne technology is expected to create significant opportunities for market growth in the coming years.

No comments:

Post a Comment